My SD300 is electrically crippled, but I found a secondhand Invision LD that I've been trying to get running. The two machines are internally compatible, but this particular Invision LD had suffered damage in storage.

Before troubleshooting anything else, there's a fault in its height-check sensor that prevents the machine from completing its startup. As a result, the machine gets stuck in a silly repeated loop of repeatedly hooking and unhooking the iron bridge, where the height-check sensor resides.

It looked like the machine was moving the height-check sensor to the wrong position, so the table wasn't making contact with the sensor. Maybe the Y-axis isn't getting calibrated to the right position?

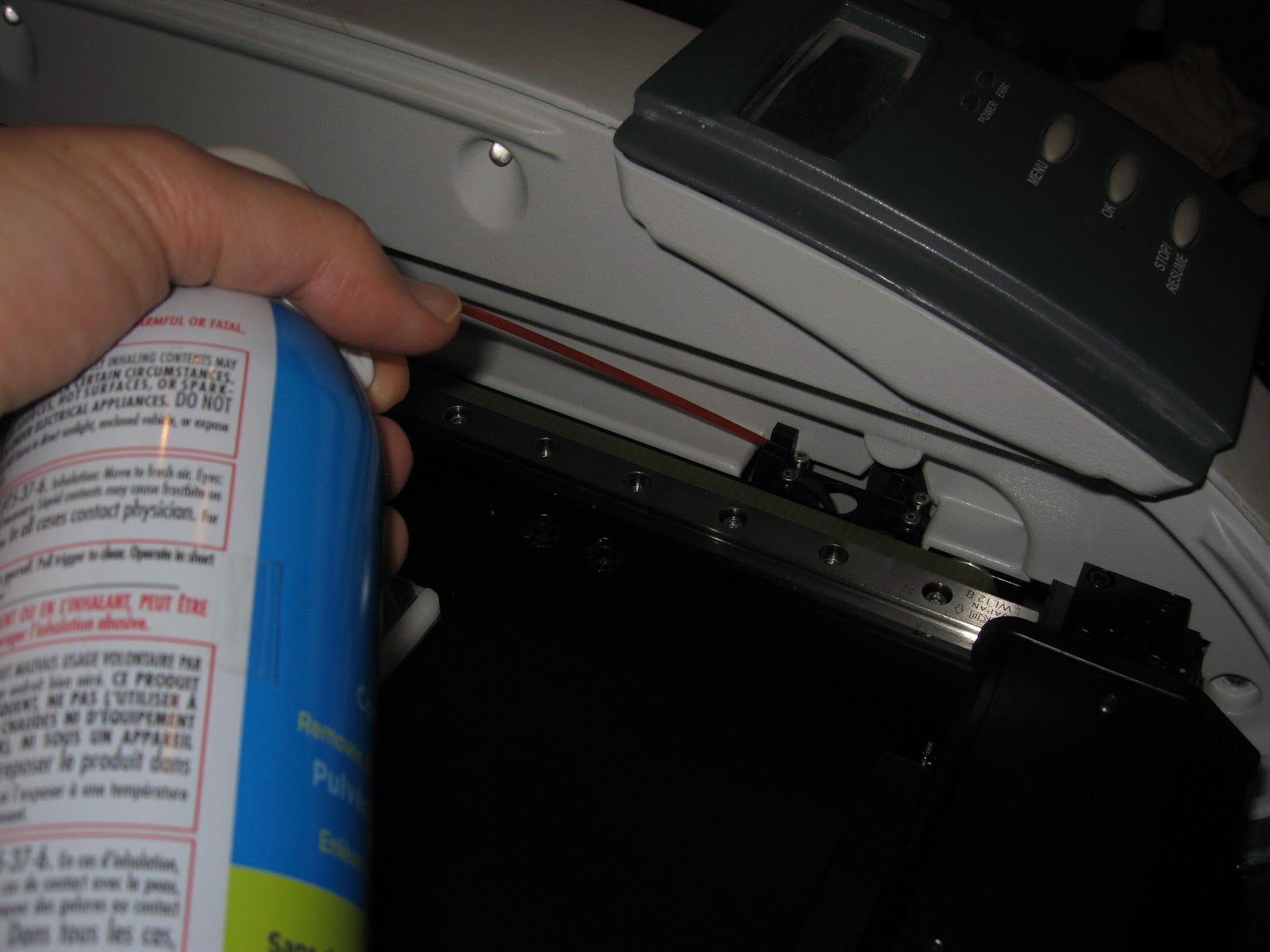

So I cleaned the Y-axis home sensors by blasting them with canned air.

That seemed to help.

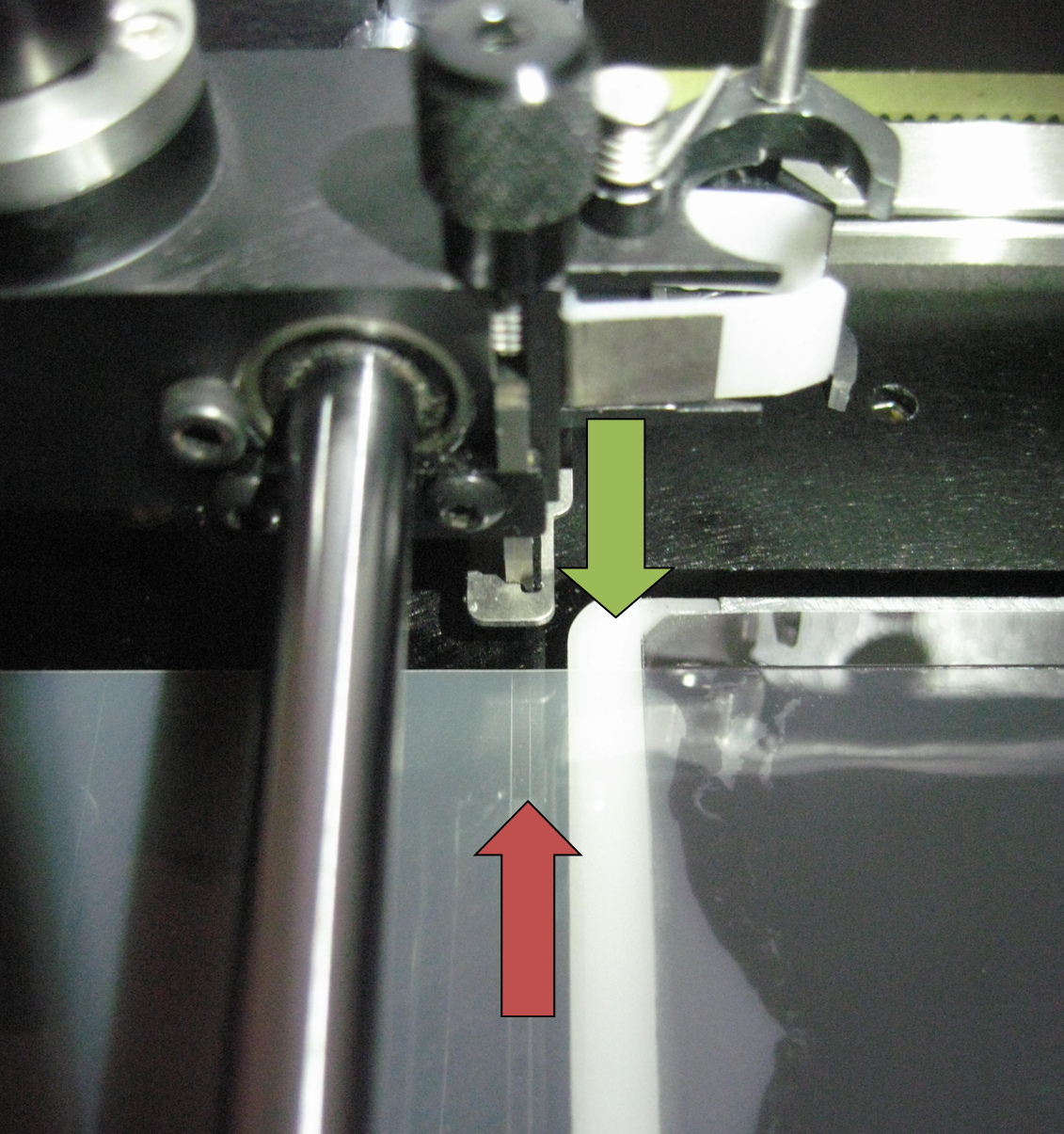

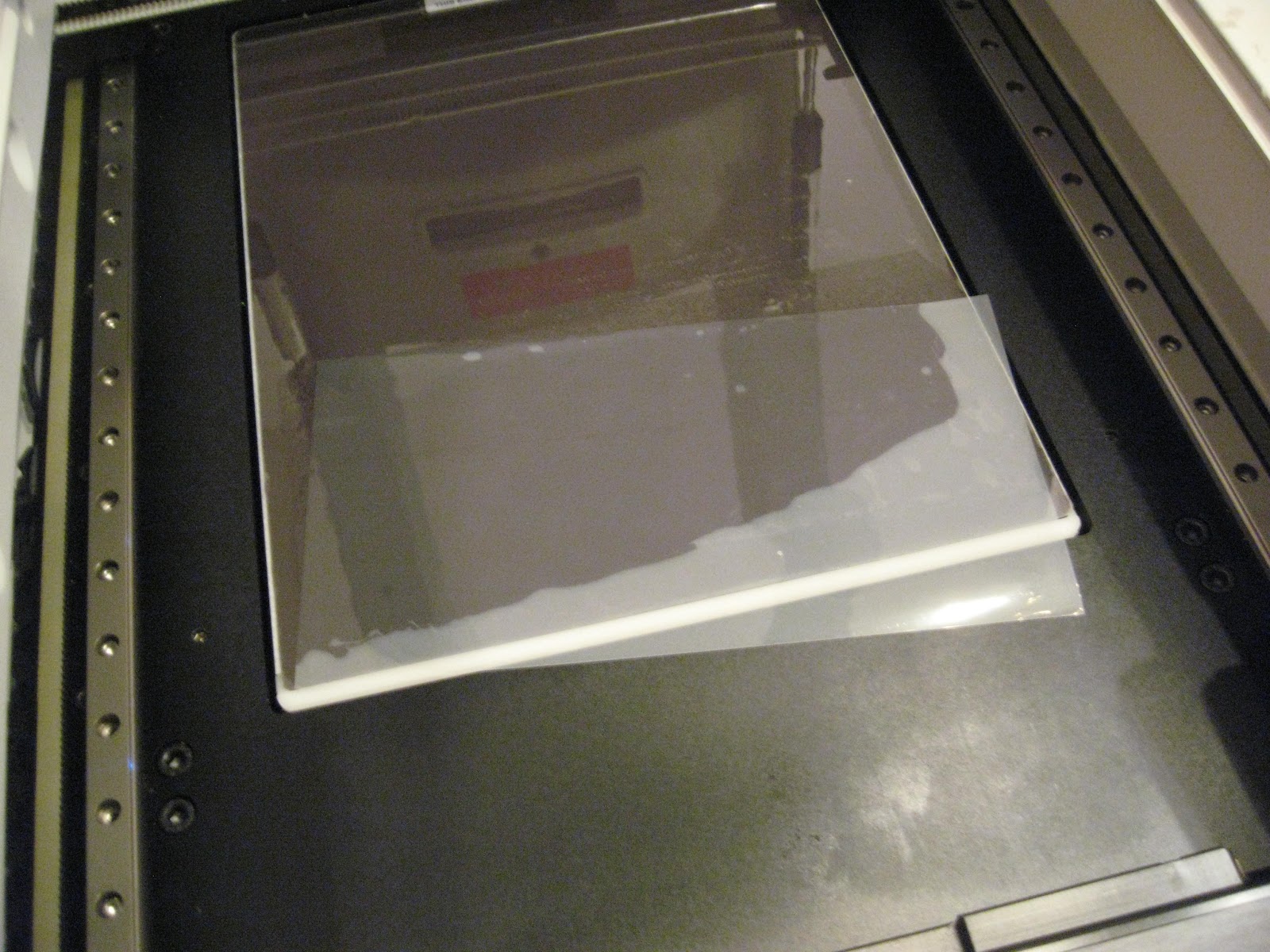

Now the machine initializes and feeds PVC onto the build table, but it intermittently fails to trim the material. To trim the PVC, the machine is supposed to raise the build table until the white cutting board (green arrow) makes contact with the trimming knife. But the Y-axis position is still wrong, so it's positioning the trim knife too far away from the table (red arrow). I used the maintenance utility to re-calibrate "accurate XY home" but then the machine was even farther out of calibration!

So, what gives?

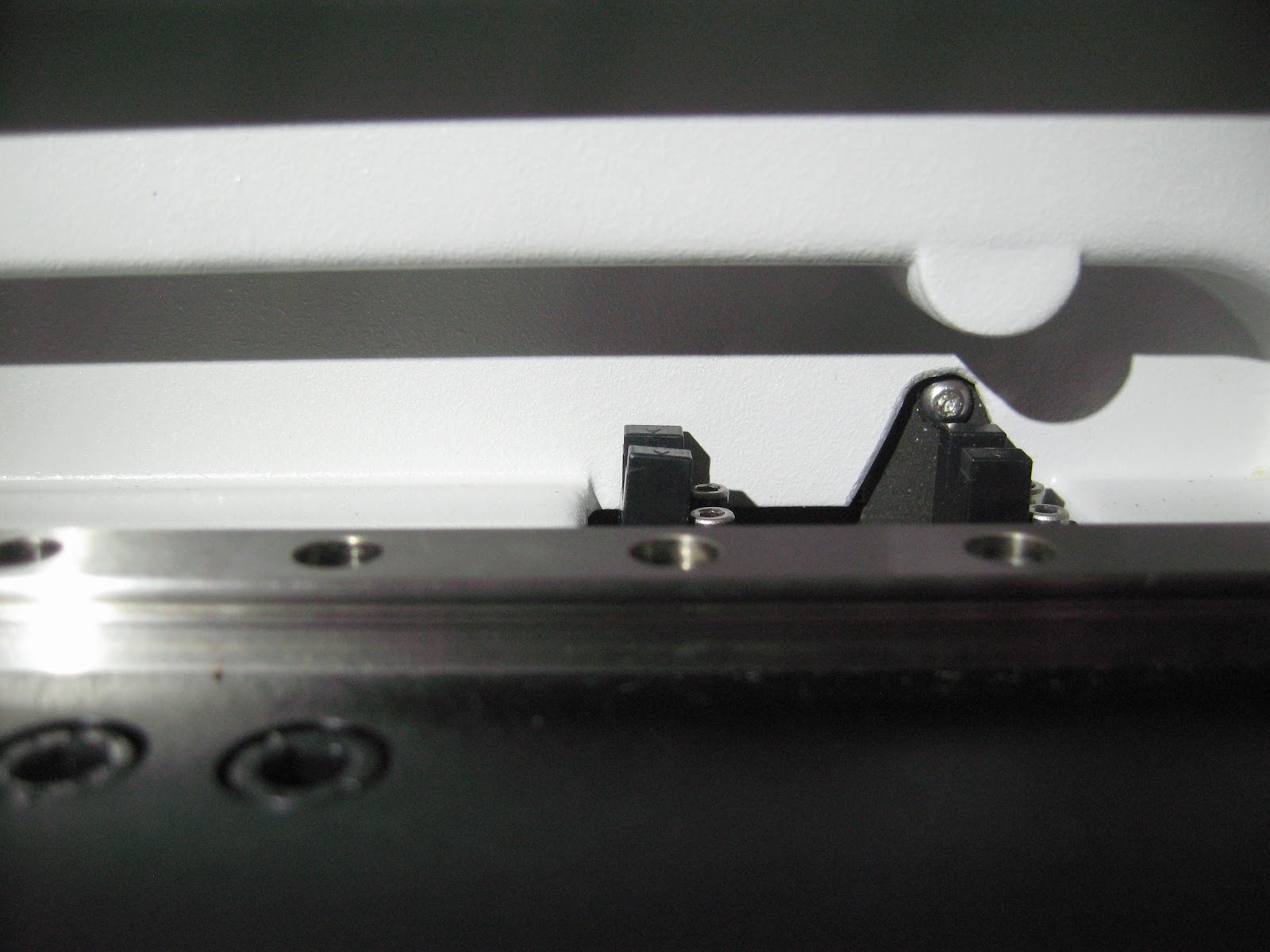

I lowered my camera into the machine and took a picture of the Y-axis home sensors.

The picture suggests the sensor on the left has been bent out of shape, possibly by an impact. The two sides should be absolutely parallel, but the nearer side has been bent to the right. It looks like its base is cracked through the mounting screws, which undoubtedly interferes with accurate sensing. That probably accounts for a lot of the machine's odd behaviors.

All right, I will replace this damaged sensor with an identical part from my SD300 and try again.

(Hoping.)